What we

Do

It takes a lot of work to design and build a concrete canoe…

|

Hull Design

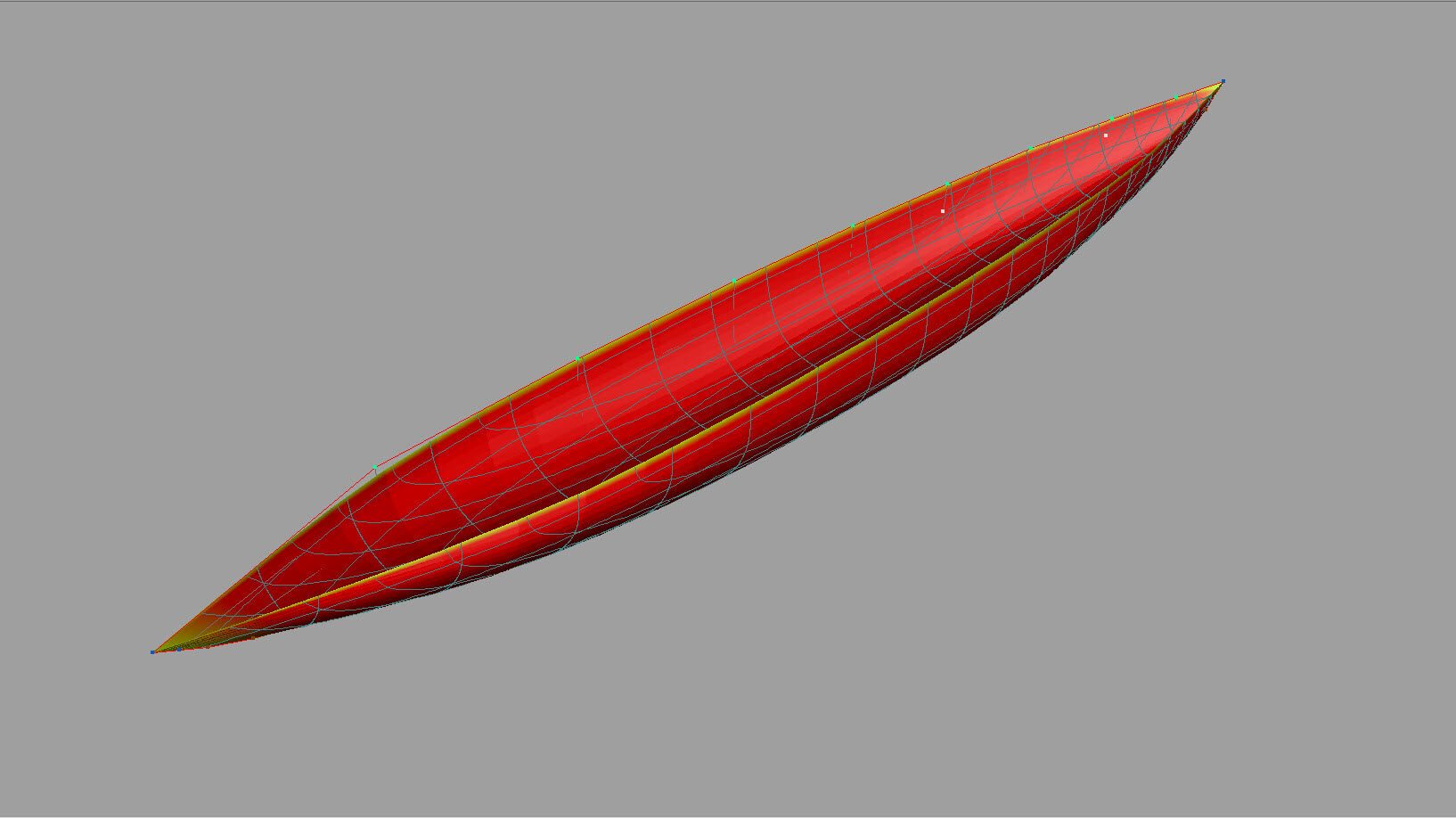

The canoe’s hull is highly optimized to ensure structural integrity, speed, and stability during the races. The team works with tools including physical and computer modelling to refine the shape of the canoe. The Hull Design team is also responsible for designing and producing the canoe’s mould.

|

Mix Design

The canoe floats thanks to our unique lightweight concrete design, which is as little as 80% of the density of water. The team spends the entire year designing concrete mixes, incorporating new materials and colours each year. We test and refine the concrete to develop a final design for each year’s canoe.

|

Construction

The effort of the entire team is needed on Casting Day. We prepare the mould, mix the concrete and construct the canoe in one 10-hour long effort. Months of planning are completed ahead of casting day, because we only have one shot to get it right. After 28 days, the canoe is taken out of the mould and final preparations are made for competition.